Empowering excellence

Personalised implants with AI-assisted platform

Meticuly’s technology is a transformative force, seamlessly merging cutting-edge innovations to reshape the landscape of healthcare. By seamlessly fusing AI-powered precision with advanced 3D printing, we empower surgeons with unparalleled tools to deliver bespoke solutions. Our technology isn’t just about improving clinical outcomes; it’s a testament to our unwavering commitment to redefining medical excellence and prioritizing the well-being of every patient.

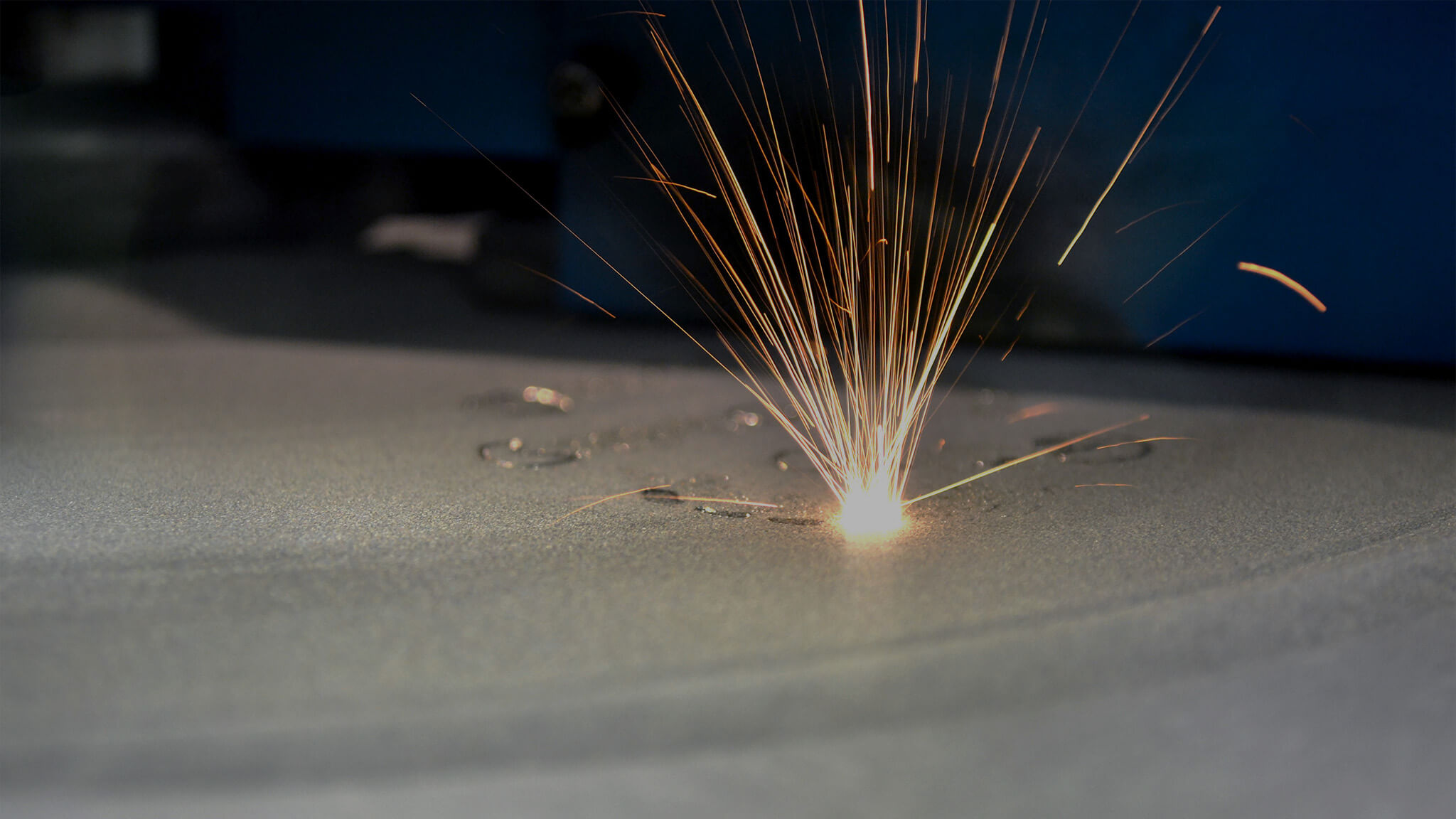

Advanced 3D Printing

We use SLM 3D printing technology to construct your implants. With Selective Laser Melting(SLM) technologies, it creates parts additively by fusing metal powder particles together in a full melting process. Consequently, the mechanical strength of every customized implant is guaranteed regardless of shape and size. This technology allows us to produce such an advanced and complex shape at the very high precision (micron scale). 3D printed Titanium implants are exceptionally biocompatible with patients’ bodies. With its low toxicity, we can ensure the patient’s infection rate as well as satisfaction level.

Beyond the powerful technology

Our dedicated support team is committed to channel your energy and time

where it truly matters.

Handled by meticulous engineers

Our dedicated support team seamlessly complements our advanced technology, working in harmony to alleviate your energy and save your valuable time. With their expertise and commitment, you can focus on what truly matters – providing exceptional care to your patients.

Ever Increasing Precision

By working constantly with surgeons in cadaveric studies and clinical cases, our platforms become more accurate each day. An ever growing database makes our products more precise. We make the most out of the technology to constantly improve our product.